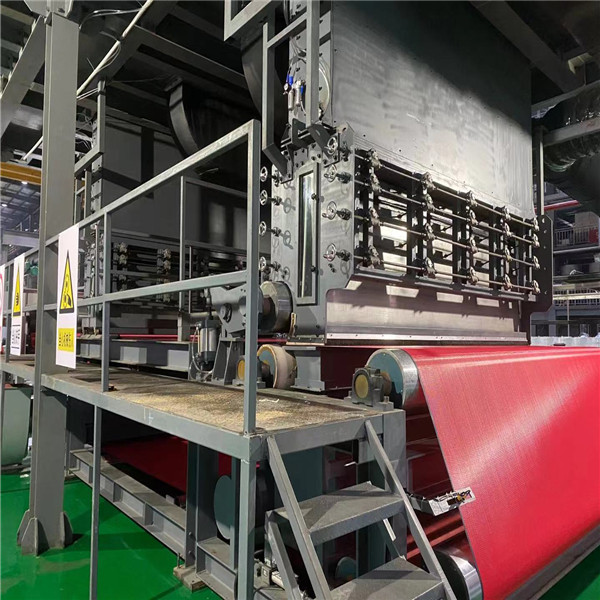

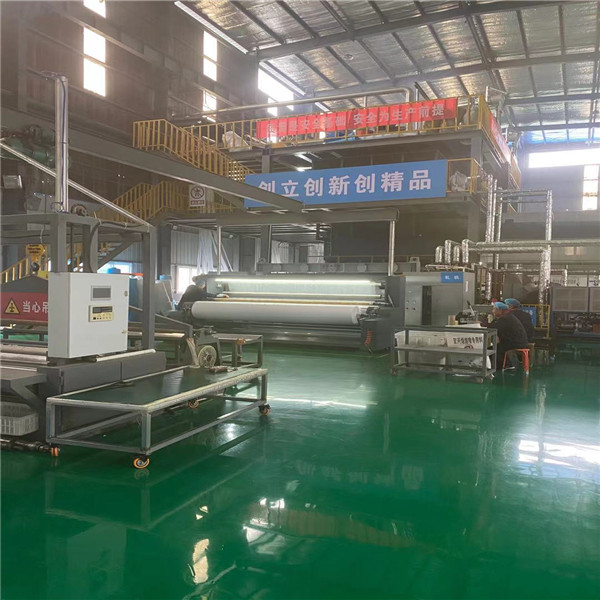

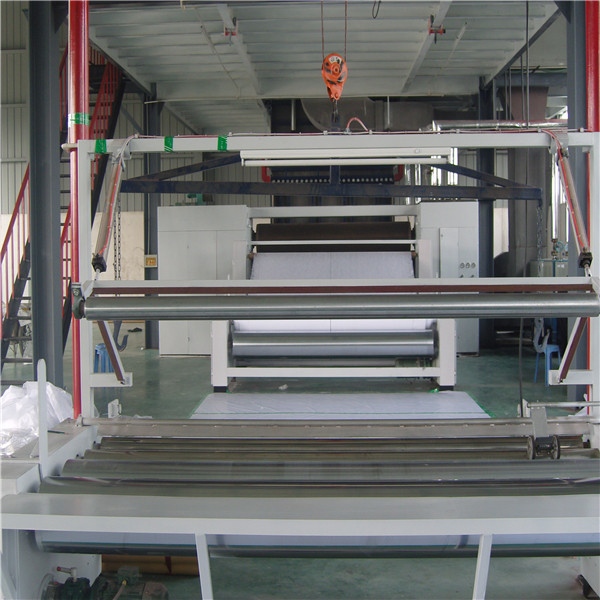

1600mm Melt-Blown Indwangu Ukwenza Machine PP Nonwoven Machine Production Line

Ukuzibophezela, ukubopha okushisayo, ukuhlanganiswa kwamakhemikhali noma ukuqiniswa okuvilaphayo kungenza iwebhu ibe yindwangu engalukiwe. Inezici zamandla aphakeme, ukumelana nokushisa okuphezulu, ukusebenza kahle okuhle, ukumelana nokuguga, ukumelana ne-UV, isilinganiso esiphakeme sokwelula, amandla nokuqina komoya, ukumelana nokugqwala, ukuvimbela umsindo, nokumelana nenundu Imikhiqizo eyinhloko yezindwangu ezingezona ezelukiweyo ze-spunbond ziboshwe izindwangu ezingezona ezelukiwe, i-polyester (i-fiber ende, i-fiber okuyisisekelo) neminye imikhiqizo. Sivame kakhulu futhi sisetshenziswa kakhulu izikhwama ezingalukanga, ukupakisha okungalukanga, njll. Kulula ukuyisebenzisa futhi kulula ukuyibona, ngoba izici zezindwangu ezingalukiwe eziphothiwe ziningi. Izinga lokusetshenziswa nalo lingenziwa ngendwangu yokupakisha imbali, indwangu yemithwalo, njll., Anti-wear, ukuzwa okuhle kwesandla, njll., Kumenze abe yisinqumo esihle sokwenza imikhiqizo enjalo.

Inqubo ukukhiqizwa ulayini Nonwoven

Izidingo zokusebenza nezokulondolozwa zikalayini wokukhiqiza ongaxhunyiwe

(1) Kunezingxenye eziningi ezibalulekile kulayini wokukhiqiza ongaphothi we-spunbond, lezi zingxenye zidinga ukubekwa endaweni ngemuva kokusetshenziswa, futhi insimbi idinga ukuvalwa. Ulayini wokukhiqiza wendwangu ongalukwanga we-spunbond akufanele uhlanganiswe ngezinto ezivuthayo neziqhumayo, futhi akukho doti engaphandle okufanele ibekwe kulayini wokukhiqiza wendwangu ongalukwanga we-spunbond. Itafula kufanele ligcinwe lihlanzekile, futhi amanye amabala kawoyela nokugqwala kufanele asulwe ahlanzeke.

(2) Izingxenye zangaphakathi zomshini wolayini wokukhiqiza ongavukiwe we-spunbond awufani namabhere, amagiya, njll., Okudingeka ukuthi ahlolwe ngokucophelela ngenkathi yokusebenza nokusebenza kwenqubo, nokuqinisekisa ukuthi lezi zingxenye zingasebenza ngokujwayelekile. Kwezinye izingxenye okulula ukuzigqoka futhi zehlulekile, kumele zishintshwe ngomshini ngesikhathi. Ama-motors, amabhokisi wamagiya, amasondo wokuvumelanisa, njll. Wolayini wokukhiqiza wendwangu ongalukwanga we-spunbond kufanele unakekelwe kahle, futhi amasekethe nezinqubo zemishini ngaphakathi kufanele zihlanzwe futhi zilungiswe.

(3) Ulayini wokukhiqiza ongaphothi we-spunbond kwesinye isikhathi unamaphutha amaningi. Amanye amaphutha, afana nemisindo engajwayelekile, isiminyaminya, njll., Angaqedwa ngokusebenza ngesandla. Kwezinye izingxenye ezinokudluliswa kwangaphakathi kaningi, uwoyela othile wokuthambisa ungangezwa ukuqinisekisa ukusebenza kahle kwemishini nemishini.

Izidingo zokusebenza nokugcinwa okungenhla zibaluleke kakhulu futhi zinenjongo kulayini wokukhiqiza ongaphothi we-spunbond. Uma ufuna ukucubungula imikhiqizo engeyona ephothiwe yekhwalithi ephezulu ye-spunbond, indwangu enhle ye-spunbond engalukwanga Ulayini wokukhiqiza awenele. Kuyadingeka futhi ukuhambisana nemithetho yokusetshenziswa enqubeni yokukhiqiza yansuku zonke ukuqinisekisa ikhwalithi yokusebenza nomsebenzi wokulungisa. Ukucaciswa kolayini wokukhiqiza ongaphothi we-spunbond yenkampani yethu kuyahlukahluka kakhulu, futhi sikholelwa ukuthi kuhlale kukhona okukufanele.

umdwebo oningiliziwe

Imininingwane yokucaciswa

| INTO | UBubanzi BOKUSEBENZA | I-GSM | UMPHUMELA WONYAKA | ISIKHATHI SOKUSEBENZA |

| S | 1600MM | 8-200 | 1500T | IDayimane, okusaqanda, isiphambano nomugqa |

| S | 2400MM | 8-200 | 2400T | IDayimane, okusaqanda, isiphambano nomugqa |

| S | 3200MM | 8-200 | 3000T | IDayimane, okusaqanda, isiphambano nomugqa |

| SS | 1600MM | 10-200 | 2500T | IDayimane, okusaqanda, isiphambano nomugqa |

| SS | 2400MM | 10-200 | 3300T | IDayimane, okusaqanda, isiphambano nomugqa |

| SS | 3200MM | 10-200 | 5000T | IDayimane, okusaqanda, isiphambano nomugqa |

| I-SMS | 1600MM | 15-200 | 2750T | Idayimane ne-oval |

| I-SMS | 2400MM | 15-200 | 3630T | Idayimane ne-oval |

| I-SMS | 3200MM | 15-200 | 5500T | Idayimane ne-oval |

Izici zokusebenza kwemishini yobuchwepheshe engalukwanga

Isidingo sezindwangu ezingalukiwe emakethe yamanje sisenkulu kakhulu. Ungakufinyelela kanjani ukukhiqizwa okusheshayo kwenqwaba yezindwangu ezingalukiwe kudinga ukusetshenziswa kwemishini nemishini ethile ezenzakalelayo. Imishini ezenzakalelayo yemishini inganikeza ngokukhipha okuphezulu nekhwalithi ephezulu yezindwangu ezingalukiwe. Kubaluleke kakhulu ukusebenzisa imishini engeyona ephothiwe yobungcweti yalokhu. Manje abakhiqizi bendwangu abaningi abangalukanga badinga ukusebenzisa imishini engalukanga. ka. Ngakho-ke yiziphi izici zokusebenza kwemishini engeyona ephothiwe yobungcweti? Ake sikubheke ndawonye.

1.Imishini engeyona ephothiwe yobungcweti yenziwe kahle ngesakhiwo, futhi icwebezela okokuqala ngqa. Imishini engalukiwe ingahlanganisa wonke amathuluzi adingekayo ekusetshenzisweni okungasuki ekwakhiweni okukodwa ukufeza ukuhlangana okuhlangene. Ngakho-ke, imishini engeyona ephothiwe yobungcweti ejwayelekile ivame ukuba mncane ngosayizi.

2. Ukusebenza okuzinzile kuyimfuneko ebalulekile yokuqinisekisa ukukhishwa kanye nekhwalithi yezindwangu ezingalukiwe. Imishini engalukiwe engaqhubeka nokugcina ukusebenza okuzinzile ingahlanganisa ikhwalithi yemikhiqizo engalukwanga futhi izuze imiphumela emihle yamanani omkhiqizo. Umkhiqizo udlala indima yokushayela.

3. Imishini engalukwanga yamukela ifreyimu yephrofayili ye-aluminium njengomzimba omkhulu, isakhiwo siqinile futhi siqinile, akulula ukugqwala, futhi sinempilo ende yokusebenza. Kuyinto elula ukufaka nokugcina. Ngakho-ke, ulwazi lokusebenzisa imishini engalukiwe luhle impela. .

4. I-othomathikhi imodi yokulawula yemishini engalukiwe ingabona ukukhiqizwa okungekho nokwelukiweyo okusheshayo futhi kwe-batch, ngakho-ke kungakhuphula kakhulu ukukhishwa kwemikhiqizo engalukanga, kunciphise izindleko zabasebenzi, futhi kulethe izinzuzo eziphakeme ebhizinisini. .

Imishini yobuchwepheshe engalukiwe enezici ezivelele ezingenhla ngokwemvelo inesikhundla esibaluleke kakhulu emkhakheni wokulungiswa okungalukiwe. Uma usebenza kumkhakha wokulungiswa komkhiqizo wezindwangu, khona-ke kuzodingeka ucabangele ukuthenga indwangu esezingeni eliphakeme yobungcweti engalukanga imishini yokuphotha. Isisetshenziswa sokusebenza okuzenzakalelayo sokusebenza okuzenzakalelayo singanikeza usizo oluhle kwimisebenzi yakho yokukhiqiza futhi sikusize uthuthukise ukusebenza kahle kokukhiqiza. Ngalokhu, umenzi wethu uphinde anikeze amamodeli wemishini eminingi yobuchwepheshe. Uma ufuna ukwazi ngokungalukiwe Ngeminye imininingwane eyisisekelo ngemishini yendwangu, ungafika kumkhiqizi wethu ukuze abukeke.