PP Meltblown Production Nonwoven Indwangu Ukwenza Machine Production Line

Inqubo yokwenziwa kwendwangu engalukanga

Ukucaciswa komugqa wokukhiqiza ongasuki

| I-SS (Ububanzi obuvelisiwe) | 1600mm | 2400mm | 3200mm |

| Izinsiza kusebenza | 29x13x10m | 30x14x10m | 32x15x10m |

| Ijubane | 350m / iminithi | 350m / iminithi | 30m / iminithi |

| I-Gram Weighht | 10-150g / m2 | 10-150g / m2 | 10-150g / m2 |

| Ukukhiqiza (Imikhiqizo ngokuya ngo-20g / M2) | 9-10T / Izinsuku | 13-14T / Izinsuku | 18-19T / Izinsuku |

| INTO | UBubanzi BOKUSEBENZA | I-GSM | UMPHUMELA WONYAKA | ISIKHATHI SOKUSEBENZA |

| S | 1600MM | 8-200 | 1500T | IDayimane, okusaqanda, isiphambano nomugqa |

| S | 2400MM | 8-200 | 2400T | IDayimane, okusaqanda, isiphambano nomugqa |

| S | 3200MM | 8-200 | 3000T | IDayimane, okusaqanda, isiphambano nomugqa |

| SS | 1600MM | 10-200 | 2500T | IDayimane, okusaqanda, isiphambano nomugqa |

| SS | 2400MM | 10-200 | 3300T | IDayimane, okusaqanda, isiphambano nomugqa |

| SS | 3200MM | 10-200 | 5000T | IDayimane, okusaqanda, isiphambano nomugqa |

| I-SMS | 1600MM | 15-200 | 2750T | Idayimane ne-oval |

| I-SMS | 2400MM | 15-200 | 3630T | Idayimane ne-oval |

| I-SMS | 3200MM | 15-200 | 5500T | Idayimane ne-oval |

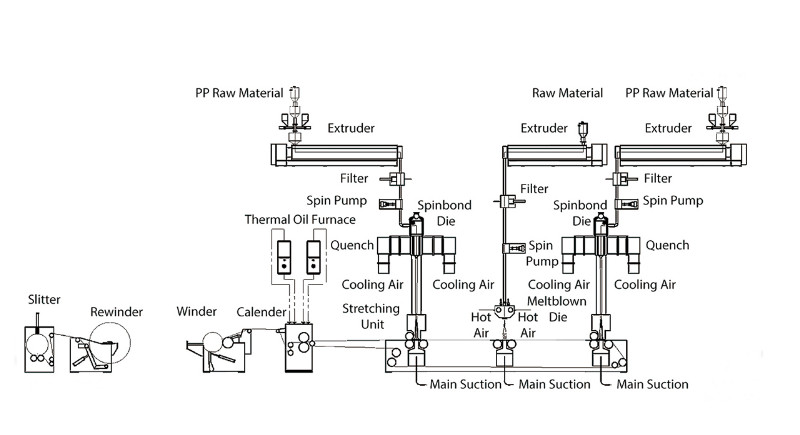

Isakhiwo sohlelo lomugqa wokukhiqiza

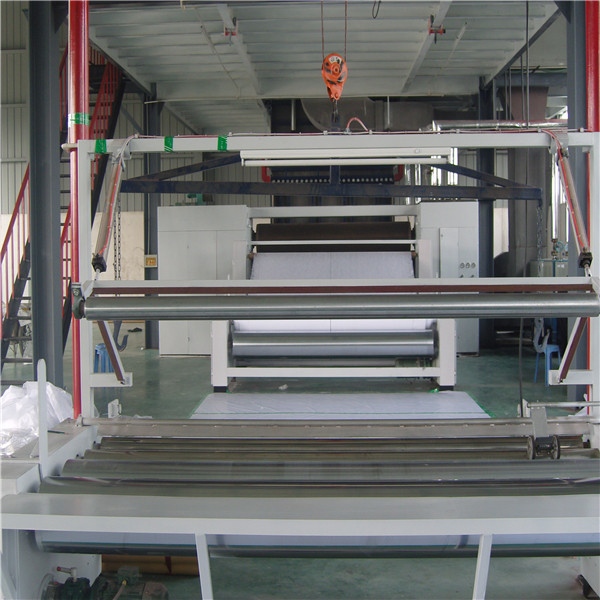

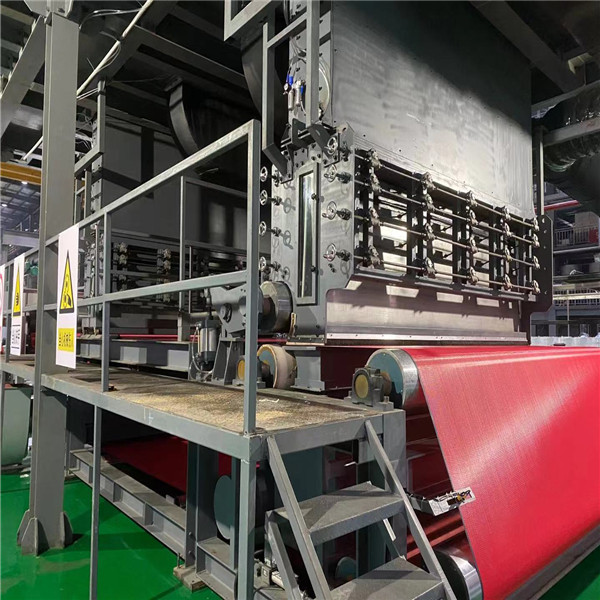

Ulayini wokukhiqiza wendwangu ongalukwanga we-spunbond uyinkimbinkimbi kakhulu kepha ihlakaniphile imishini yokulungisa imishini. Ngezansi, umhleli uzokukhombisa izingxenye ezimbili ezinkulu zomugqa wokukhiqiza ongavukiwe we-spunbond ngokuningiliziwe.

Izingxenye ezimbili ezinkulu zomugqa wokukhiqiza ongaphothi we-spunbond

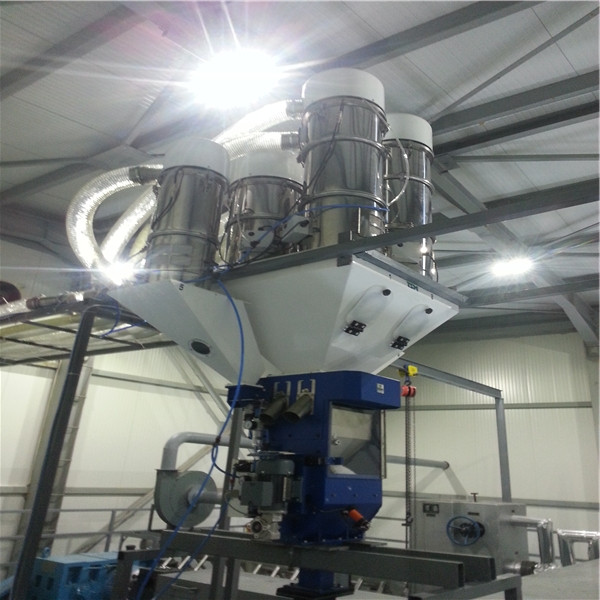

Uhlelo lokuhambisa: Olokuqala uhlelo lokudlulisa lukalayini wokukhiqiza ongasuki we-spunbond. Uhlelo lokudlulisa lubandakanya izinto ezimbili, shaft yokudlulisa yangaphakathi nezingxenye ezihlobene nayo, nebhande lokudlulisa elingaphandle. Ibhande lokudlulisa langaphandle lakhiwe kakhulu ngedivayisi yokuphakela, idivaysi yokudlulisa kanye nedivayisi yokugcina. Idivayisi ngayinye ihambelana nenqubo ehlukile yokukhiqizwa kwendwangu ye-spunbond non-woven. Umshini wonke uqhutshwa yi-shaft enkulu yangaphakathi yedrayivu, bese-ke ingafinyelela umphumela wokucutshungulwa kokuhanjiswa kwezinto okuphezulu kakhulu.

Isistimu yokulawula: Njengoba igama lisho, uhlelo lokulawula uhlelo olulawula ukusebenza kwalo lonke ulayini wokukhiqiza we-spunbond nonwoven. Isinciphisi ngaphakathi kukalayini wokukhiqiza ongasetshenziswanga we-spunbond siguqula amasiginali kagesi abe yizenzo zomshini, bese sisekela ukusebenza kwazo zonke izingxenye zokudluliswa komshini kulayini wokukhiqiza ongasetshenziswanga owenziwe ngesipuni. Ngasikhathi sinye, ulayini wokukhiqiza we-spunbond nonwoven futhi unomsebenzi wokuguqula wezindlela eziningi zokulawula, ngokwesibonelo, ungashintshwa phakathi kokuzenzekelayo, oku-semi-othomathikhi nokwenziwa ngesandla, ukuze kuhlangatshezwane nezidingo zokusebenza komugqa wokukhiqiza ongaphothiwe ophothiwe ngaphansi izidingo ezahlukene zokukhiqiza.

Lezi zingxenye ezimbili ezingenhla zakha umugqa wokukhiqiza wendwangu ongavukiwe ohlanganisa i-spunbond, enikeza isiqinisekiso esinamandla nesinokwethenjelwa sehardware sokukhiqizwa kwezindwangu ezingalukiwe eziphothiwe. Ngokuthuthuka okuqhubekayo kobuchwepheshe bokukhiqiza, izintambo eziningi zokukhiqiza ezingavukiwe ze-spunbond seziqale ukwehlisa amanani futhi zaziwa, futhi abakhiqizi abaningi sebeqalile ukubazisa. Isethi yonke yemishini enikezwe ngumkhiqizi wolayini wethu wokukhiqiza ongasuki we-spunbond ungokuqukethwe okuphezulu kwezobuchwepheshe, intengo yesayensi, nekhwalithi enhle kakhulu, ezoqinisekisa ukuthi uzokwaneliseka ngokusebenzisa kwakho. Uma unesifiso semishini yethu, sicela ukhululeke ukuvakashela imboni yethu.