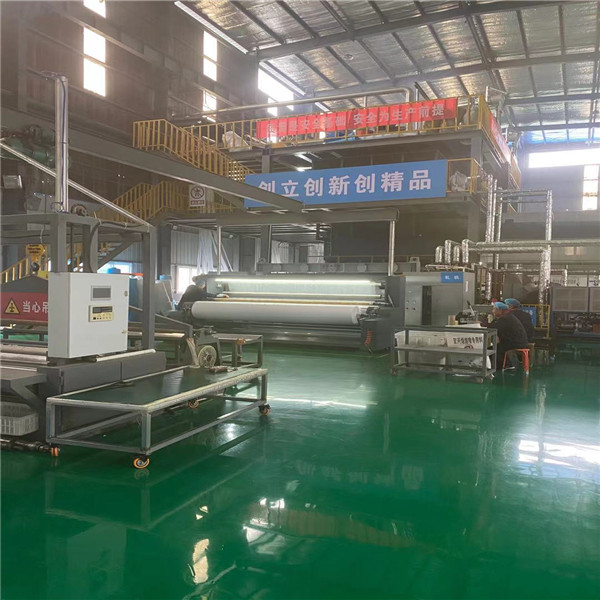

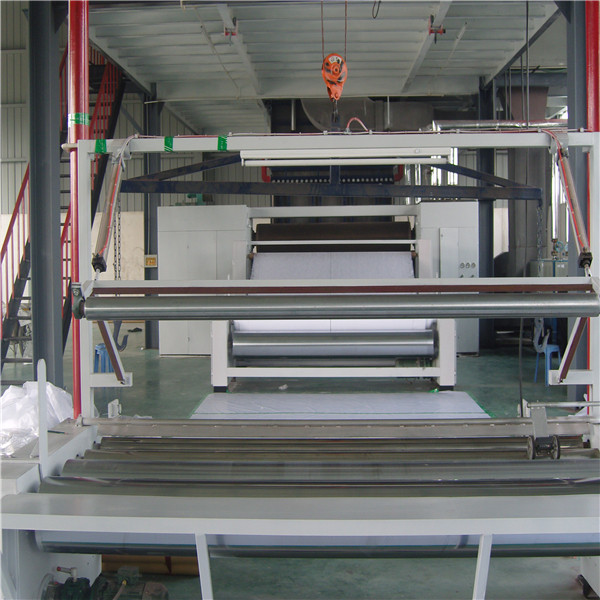

Spunmelt esiyinhlanganisela umugqa ukukhiqizwa nonwoven, spunbonded umugqa ukukhiqizwa nonwoven

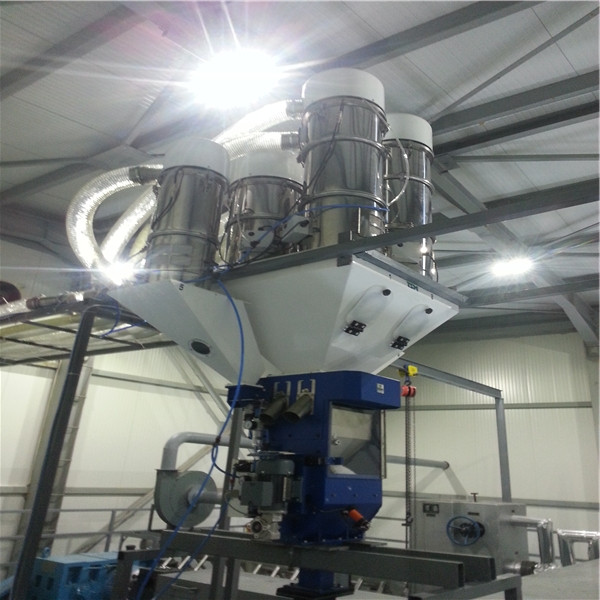

Ulayini wokukhiqiza we-Meltblown nonwoven

Izinzuzo zemishini engalukanga

1. Yonke inqubo yokugeleza kwemishini engalukiwe ingazenzekela ngokuphelele, futhi kudingeka abantu abangu-1 ~ 2 kuphela ukuthi basebenze, okungagcina abasebenzi abalinganiselwe.

2. Imishini yendwangu engalukiwe ingalungisa ijubane lokukhiqiza nosayizi womkhiqizo ngaphakathi kwebanga. Imishini yendwangu engalukiwe isebenzisa ukusebenza kwesikrini sokuthinta, ifakwe ubude obungaguquki, ukulandela ngomkhondo isithombe, ukubala okuzenzakalelayo nokubhoboza okuzenzakalelayo, njll.

3. Ukuze uqhubeke uqonde umphumela wokonga ugesi wemishini engalukanga, okokusebenza okungalukiwe kunomsebenzi wokuphinda usebenzise izinto zokwakha ezengeziwe ngesikhathi senqubo yokukhiqizwa kwemishini engalukiwe, eqoqa imfucuza esele ngesikhathi sokukhiqiza process, elusizo ekusetshenzisweni kwesibili futhi enciphisa ukuqina kwabasebenzi. Ukwandisa ukusebenza kahle komsebenzi. Ukutholwa kwezinsizakusebenza akugcini ngokusindisa izinsizakusebenza, kepha futhi kunomthelela omuhle wokuvikela imvelo.

Imishini engalukiwe

Ukucaciswa kwemishini engalukanga

| INTO | UBubanzi BOKUSEBENZA | I-GSM | UMPHUMELA WONYAKA | ISIKHATHI SOKUSEBENZA |

| S | 1600MM | 8-200 | 1500T | IDayimane, okusaqanda, isiphambano nomugqa |

| S | 2400MM | 8-200 | 2400T | IDayimane, okusaqanda, isiphambano nomugqa |

| S | 3200MM | 8-200 | 3000T | IDayimane, okusaqanda, isiphambano nomugqa |

| SS | 1600MM | 10-200 | 2500T | IDayimane, okusaqanda, isiphambano nomugqa |

| SS | 2400MM | 10-200 | 3300T | IDayimane, okusaqanda, isiphambano nomugqa |

| SS | 3200MM | 10-200 | 5000T | IDayimane, okusaqanda, isiphambano nomugqa |

| I-SMS | 1600MM | 15-200 | 2750T | Idayimane ne-oval |

| I-SMS | 2400MM | 15-200 | 3630T | Idayimane ne-oval |

| I-SMS | 3200MM | 15-200 | 5500T | Idayimane ne-oval |

Ukulethwa kwemishini engewona nokwelukiweyo

Izidingo zokusebenza nezokulondolozwa zikalayini wokukhiqiza ongaxhunyiwe

(1) Kunezingxenye eziningi ezibalulekile kulayini wokukhiqiza ongaphothi we-spunbond, lezi zingxenye zidinga ukubekwa endaweni ngemuva kokusetshenziswa, futhi insimbi idinga ukuvalwa. Ulayini wokukhiqiza wendwangu ongalukwanga we-spunbond akufanele uhlanganiswe ngezinto ezivuthayo neziqhumayo, futhi akukho doti engaphandle okufanele ibekwe kulayini wokukhiqiza wendwangu ongalukwanga we-spunbond. Itafula kufanele ligcinwe lihlanzekile, futhi amanye amabala kawoyela nokugqwala kufanele asulwe ahlanzeke.

(2) Izingxenye zangaphakathi zomshini wolayini wokukhiqiza ongavukiwe we-spunbond awufani namabhere, amagiya, njll., Okudingeka ukuthi ahlolwe ngokucophelela ngenkathi yokusebenza nokusebenza kwenqubo, nokuqinisekisa ukuthi lezi zingxenye zingasebenza ngokujwayelekile. Kwezinye izingxenye okulula ukuzigqoka futhi zehlulekile, kumele zishintshwe ngomshini ngesikhathi. Ama-motors, amabhokisi wamagiya, amasondo wokuvumelanisa, njll. Wolayini wokukhiqiza wendwangu ongalukwanga we-spunbond kufanele unakekelwe kahle, futhi amasekethe nezinqubo zemishini ngaphakathi kufanele zihlanzwe futhi zilungiswe.

(3) Ulayini wokukhiqiza ongaphothi we-spunbond kwesinye isikhathi unamaphutha amaningi. Amanye amaphutha, afana nemisindo engajwayelekile, isiminyaminya, njll., Angaqedwa ngokusebenza ngesandla. Kwezinye izingxenye ezinokudluliswa kwangaphakathi kaningi, uwoyela othile wokuthambisa ungangezwa ukuqinisekisa ukusebenza kahle kwemishini nemishini.